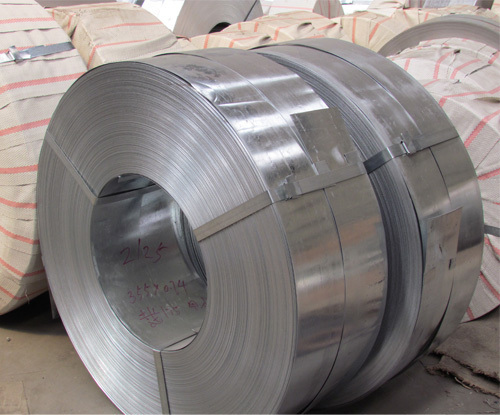

235 strip simbi

Tsanangudzo Pfupi

Iyo strip simbi inowanzo kupihwa mumakoiri, ayo ane zvakanakira yeakakwira dimensional kurongeka, yakanaka yepamusoro mhando, nyore kugadzirisa, kuchengetedza zvinhu uye zvichingodaro.Zvakangofanana neplate yesimbi, simbi yemutsetse yakakamurwa kuita yakajairwa simbi simbi uye yemhando yepamusoro simbi yemhando zvichienderana nezvinhu zvakashandiswa;Zvinoenderana nemaitiro ekugadzirisa, yakakamurwa kuita inopisa-yakavhuvhuta strip uye inotonhora-yakatenderedzwa strip.

Maitiro ekugadzira echando akakungurutswa tambo anowanzo seanotevera: kunhonga → kukungurutsira → gadzira lubrication → annealing → leveling → kugera → kurongedza.

Cold rolled strip process: Pickling - rolling - annealing - synchronous lubrication of rolling size - antirust oil - leveling and sizeing - polishing - kurongedza.

Hot strip rolling process: kupisa choto - dephosphorization muchina - roughing mill - dephosphorization muchina - yekupedzisa chigayo - pamusoro pemhando yekuongorora chiridzwa - layer inotonhorera - coiler - baler - yekumaka muchina - rolling stock slab

Inopisa yakakungurutswa tambo yekugadzira tambo: chekutanga, simudza tembiricha muchoto chekudziya kusvika kune inodiwa yekutenderedza tembiricha, wobva waisa roughing dephosphorization muchina kuburikidza netafura yeroller kurapa iyo iron oxide chiyero inogadzirwa ne slab, wobva wapinda mu roughing rolling unit kuti ikunguruke. hupamhi uye ukobvu hwemutsetse, uye wobva waitakura kubva patafura ye roller kuenda kumuchina wekupedzisa dephosphorization kurapa iyo iron oxide chiyero inogadzirwa pamusoro peiyo tambo, Pinda iyo yekupedzisa rolling unit kuti unyatso kutenderera kwehupamhi uye hupamhi hwe. iyo simbi yesimbi.Mushure mekushisa kwepamusoro kwesimbi ye strip yakanyatso kudzorwa neroller tafura kuburikidza ne layer yekutonhora isati yakoira, inopinda mucoiler kuita coil yesimbi.Pakupedzisira, inounganidzwa, yakapfapfaidzwa uye inotumirwa kunzvimbo yekuchengetera coil kuti ichengete uye kurongedza.